- Shed No 20, Gala No 09, Shree Arihant Complex, Kalher, Thane, Maharashtra 421302

- mahesh@saikrishnaengineeringco.com

- kplkc@yahoo.com

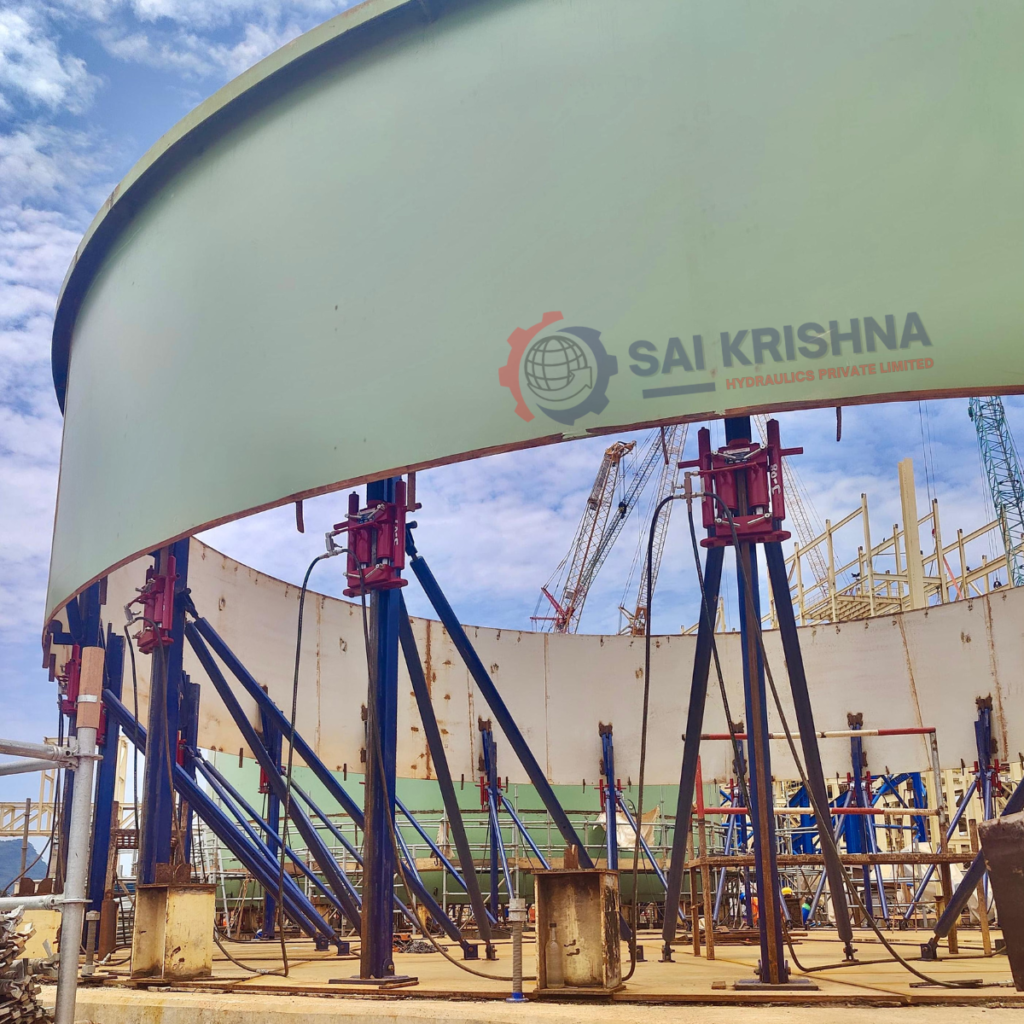

Sai Krishna Engineering Company provides an alternative tank jacking system called Tank jacking with a lifting J-hook. This type of jacking system differs from the standard method of using a lifting arm to raise the tank. Instead, it utilizes a lifting Jhook. The benefit of using the J-hook lifting system is that it removes the need for welding the lifting lugs and fend-off lugs inside the shell. As a result, there is no requirement for any post-lifting repairs or tests to be carried out.

Sai Krishna Engineering Company provides an alternative tank jacking system called Tank jacking with a lifting J-hook. This type of jacking system differs from the standard method of using a lifting arm to raise the tank. Instead, it utilizes a lifting J hook. The benefit of using the J-hook lifting system is that it removes the need for welding the lifting lugs and fend-off lugs inside the shell. As a result, there is no requirement for any post-lifting repairs or tests to be carried out.

Sai Krishna Engineering Company provides an alternative tank jacking system called Tank jacking with a lifting J-hook. This type of jacking system differs from the standard method of using a lifting arm to raise the tank. Instead, it utilizes a lifting Jhook. The benefit of using the J-hook lifting system is that it removes the need for welding the lifting lugs and fend-off lugs inside the shell. As a result, there is no requirement for any post-lifting repairs or tests to be carried out.

Sai Krishna Engineering Company provides an alternative tank jacking system called Tank jacking with a lifting J-hook. This type of jacking system differs from the standard method of using a lifting arm to raise the tank. Instead, it utilizes a lifting J hook. The benefit of using the J-hook lifting system is that it removes the need for welding the lifting lugs and fend-off lugs inside the shell. As a result, there is no requirement for any post-lifting repairs or tests to be carried out.

Sai Krishna Engineering Company provides an alternative tank jacking system called Tank jacking with a lifting J-hook. This type of jacking system differs from the standard method of using a lifting arm to raise the tank. Instead, it utilizes a lifting J hook. The benefit of using the J-hook lifting system is that it removes the need for welding the lifting lugs and fend-off lugs inside the shell. As a result, there is no requirementfor any post-lifting repairs or tests to be carried out.