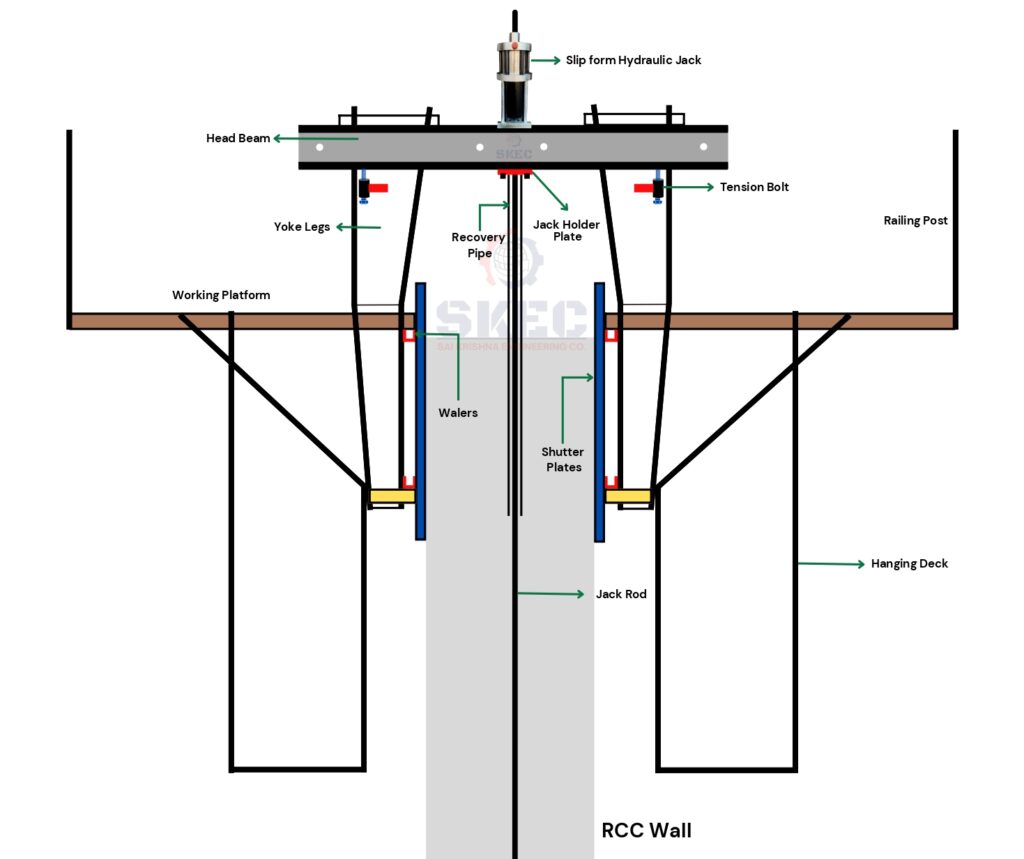

Yoke leg: The slip-form yoke leg is a vertical structural element that is an integral part of the slip-form equipment. It is designed to provide stability, alignment, and

controlled movement to the formwork as it continuously rises during the concrete pouring and curing process. It provides the necessary structural integrity to

withstand the forces exerted during the construction process. The Yoke leg guides

and supports the formwork when the pressure is applied by the hydraulic jacks, ensuring it rises at a uniform rate.

Jack rods: Slipform Jack rods are long, threaded rods that connect the formwork to the hydraulic jacks. Jacking rods act as the conduit for the hydraulic force generated by the jacks. The lifting jack climbs over the jack rod. The entire load of the Slipform assembly is transferred to jacking rods when the jacks are energized. The rods are generally 48mm, 32mm, or 25mm in diameter based on the type of the jacks.

Walers: Slipform walers are horizontal structural components used in slip-form

construction to support and stabilize the formwork. They help in distributing the load evenly, preventing deformation or failure of the formwork. Walers prevent lateral movements and ensure that the formwork remains level and properly positioned. In addition, they keep the formwork in place, prevent deformations, and ensure that the structure remains true to the intended design.

Shuttering plates: These are the vertical components that enclose the concrete being poured and play a critical role in the slip-form construction process. Shuttering panels encase the freshly poured concrete, providing the structure and shape for the slip-formed element, such as a tower, chimney, or silo. As hydraulic jacks raise the formwork, the panels move vertically at a controlled rate, enabling the structure to rise continuously. The shuttering plates contribute to achieving a smooth and uniform finish on the slip form structure, eliminating the need for frequent formwork disassembly and reassembly.

Hanging deck: A slip-form hanging deck, also known as a hanging platform or suspended platform, is a specialized component used to provide a safe and accessible workspace for construction personnel working on a vertical structure. This allows workers to carry out tasks such as applying finishes, performing inspections, and making adjustments as needed. Hanging decks are equipped with safety features such as guardrails, harness attachment points, and safety netting to ensure the protection of workers at elevated heights. They are designed to be stable and capable of supporting the weight of workers and equipment while hanging from the slip forming structure.

Railing post: A slipform railing post refers to a component of slipform construction that is used to create vertical posts or supports for railings, barriers, or other safety features on a structure. They provide vertical support and structural integrity. They help prevent falls and provide guidance and protection.

Slipform Jack: Slipform lifting jacks are specialized hydraulic devices used in slipform construction to facilitate the controlled vertical movement of the formwork as concrete is continuously poured and cured. These jacks play a crucial role in maintaining the accuracy, stability, and uniformity of the construction process.

Vertical Movement Control: The jacks are strategically positioned at intervals along the slipform structure. They work in tandem to lift the formwork

incrementally as the concrete is poured and cured, allowing for a continuous and uniform vertical progression.

Synchronization: Synchronization of the lifting jacks is crucial to prevent tilting or misalignment of the formwork. Advanced slipform systems incorporate technologies that ensure all jacks move simultaneously and maintain the desired

alignment.

Load-Bearing Capacity: Slipform lifting jacks are engineered to handle the weight of the formwork, concrete, and other components during the construction process. Their load-bearing capacity is determined based on the specific requirements of the project.

Precision and Accuracy: Slipform jacks are designed for precise and accurate movement, ensuring that the formwork maintains the intended shape and dimensions as it rises. This accuracy is essential for achieving a smooth, seamless finish.

Safety Features: Slipform lifting jacks are equipped with safety mechanisms to prevent overloading or sudden movements. Emergency stop controls and pressure relief valves contribute to a safe working environment.

Maintenance and Monitoring: Slipform lifting jacks require regular maintenance

and monitoring to ensure their proper functioning throughout the construction

process.